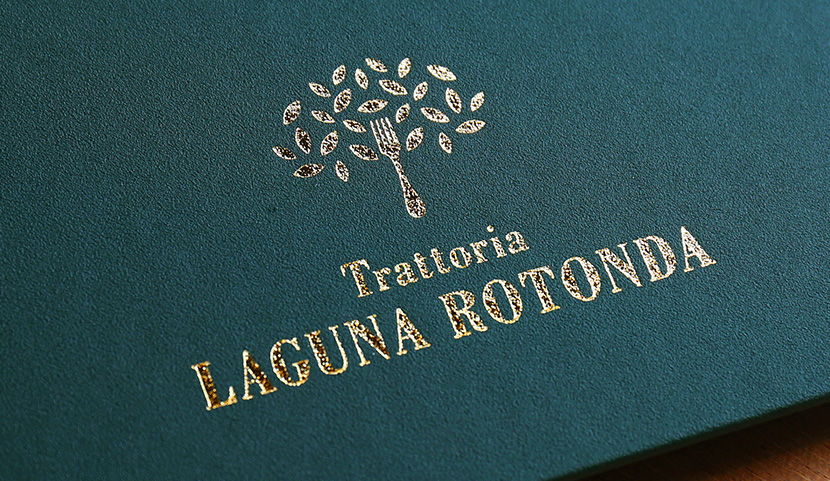

How about adding a name in your menu?

The image of your menu book can increase tremendously by adding your store name or logo.

It makes your customers remember your name and thus increases your repeated customers.

There are a number of name-adding process, let’s have a look.

Items capable for name-adding

-

Menu book

-

key holder

[About key holders]

Please type “key holder” as the searching keyword by using the text-searching engine at the top of SHIMBI online. You can find it at “guest rooms (hotels & accommodation facilities) from the category menu on the left.

《Download of various specifications》

Method of name-logo adding

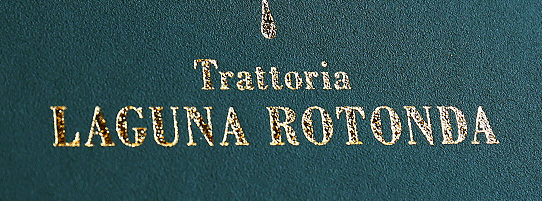

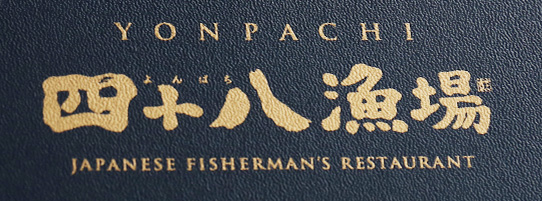

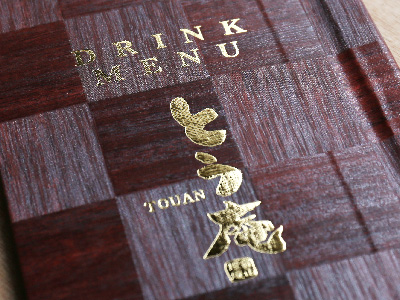

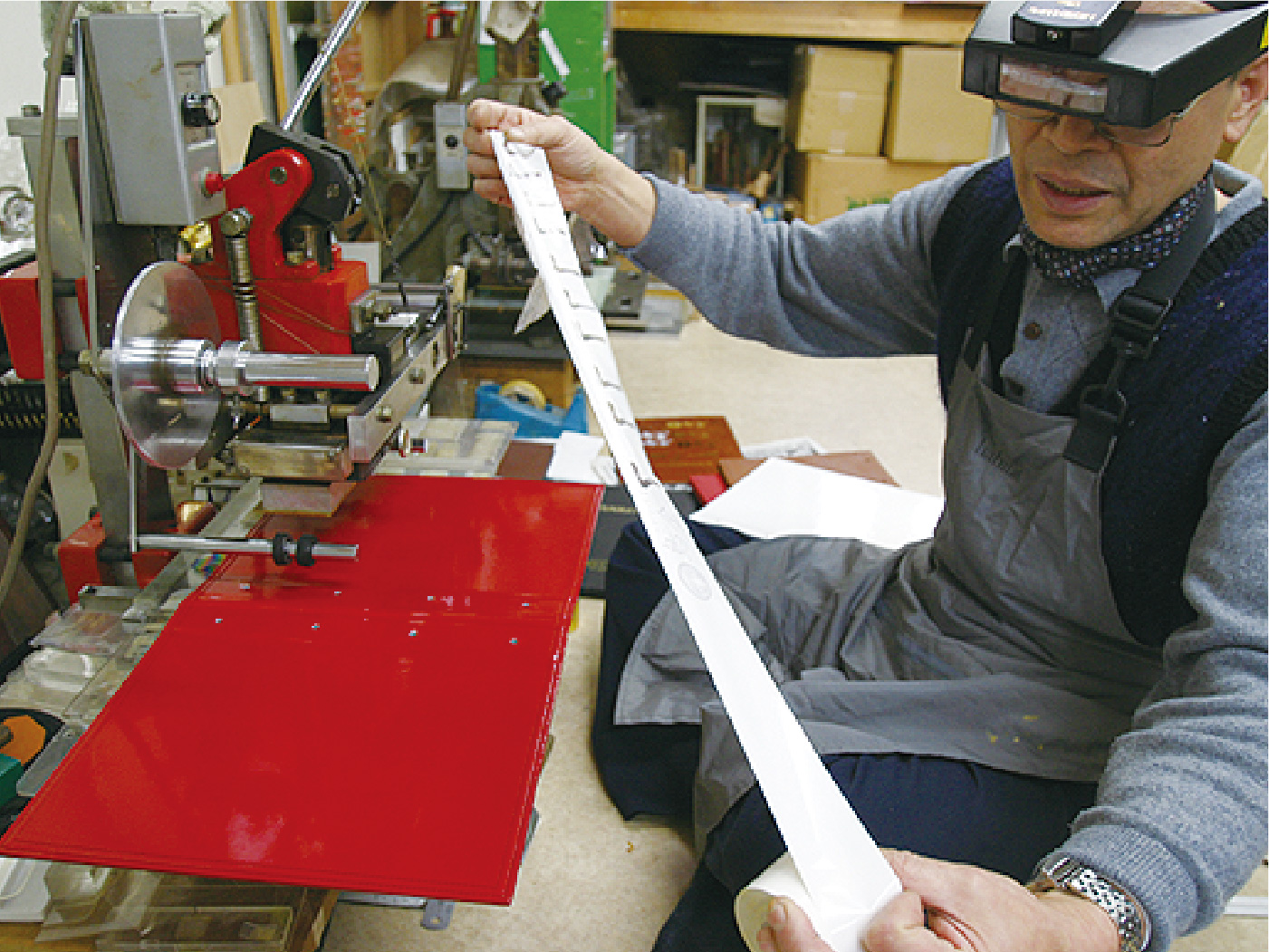

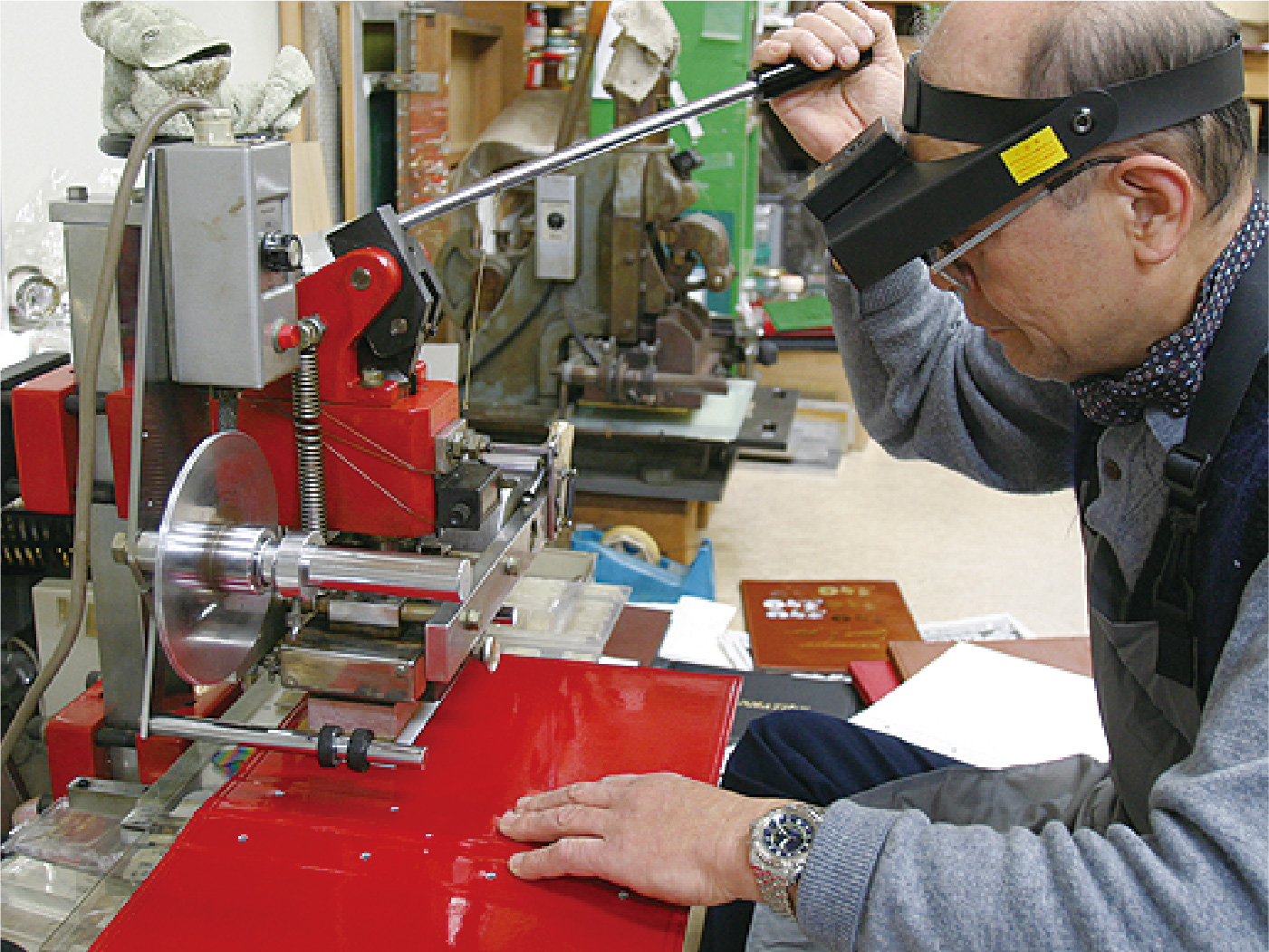

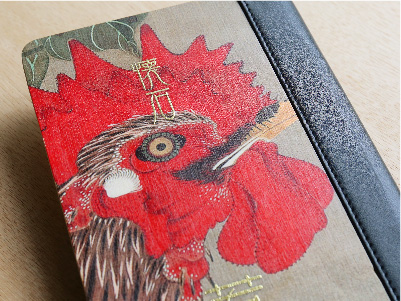

Gilding

Gilding is the application of a very thin coating (foil) to the menu through a metallic letter press.

[Features]

It is a printing of logo on the target surface through high temperature and high pressure. Depending on the texture of the target surface, dents may form, and there is a simple kind of foil-less gilding called “simplified gilding” (or alternatively called blank gilding). (Please refer to 02 simplified gilding)

> Operation process

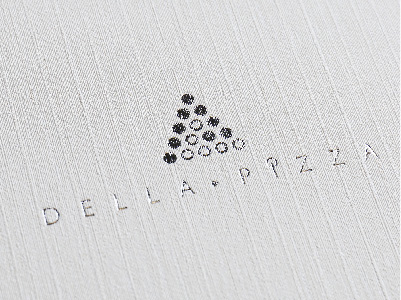

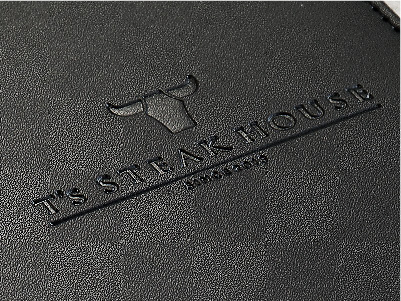

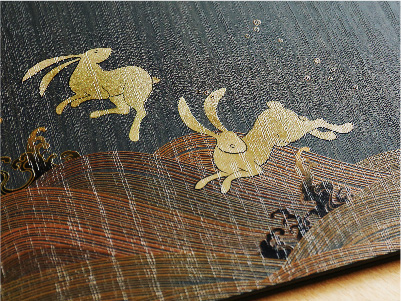

Simplified gilding

It’s almost the same as gilding but just without a film (foil) so the letter press is directly pushed onto the printing surface.

[Features]

It is a printing of logo on the target surface through high temperature and high pressure. Depending on the texture of the target surface, dents may form. As no foil is used, this printing is good as a simple design without colors.

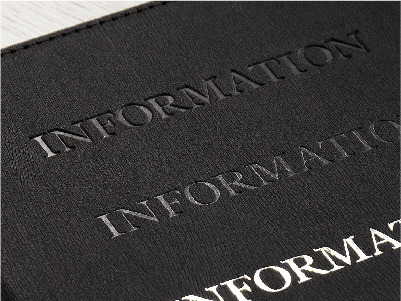

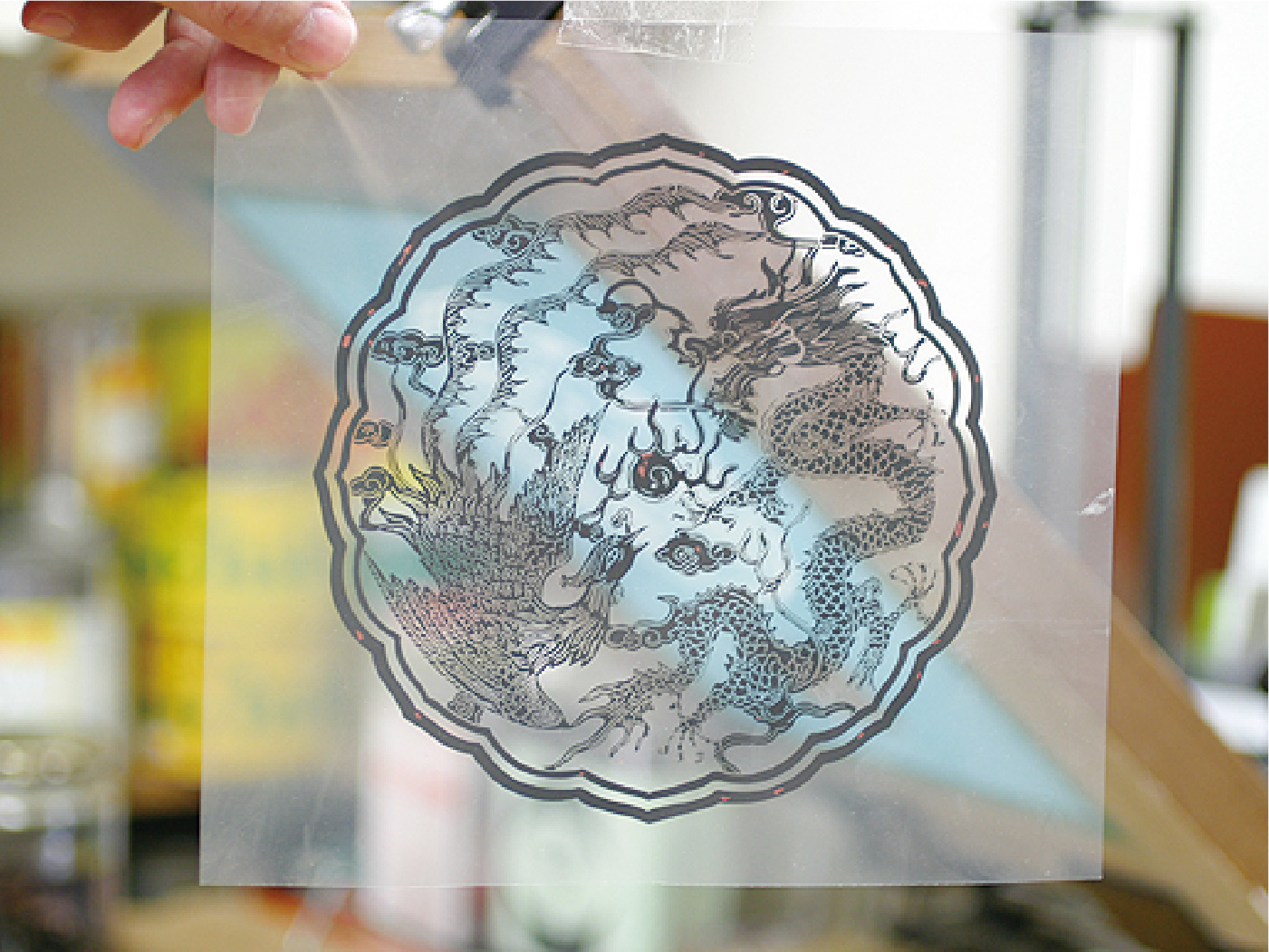

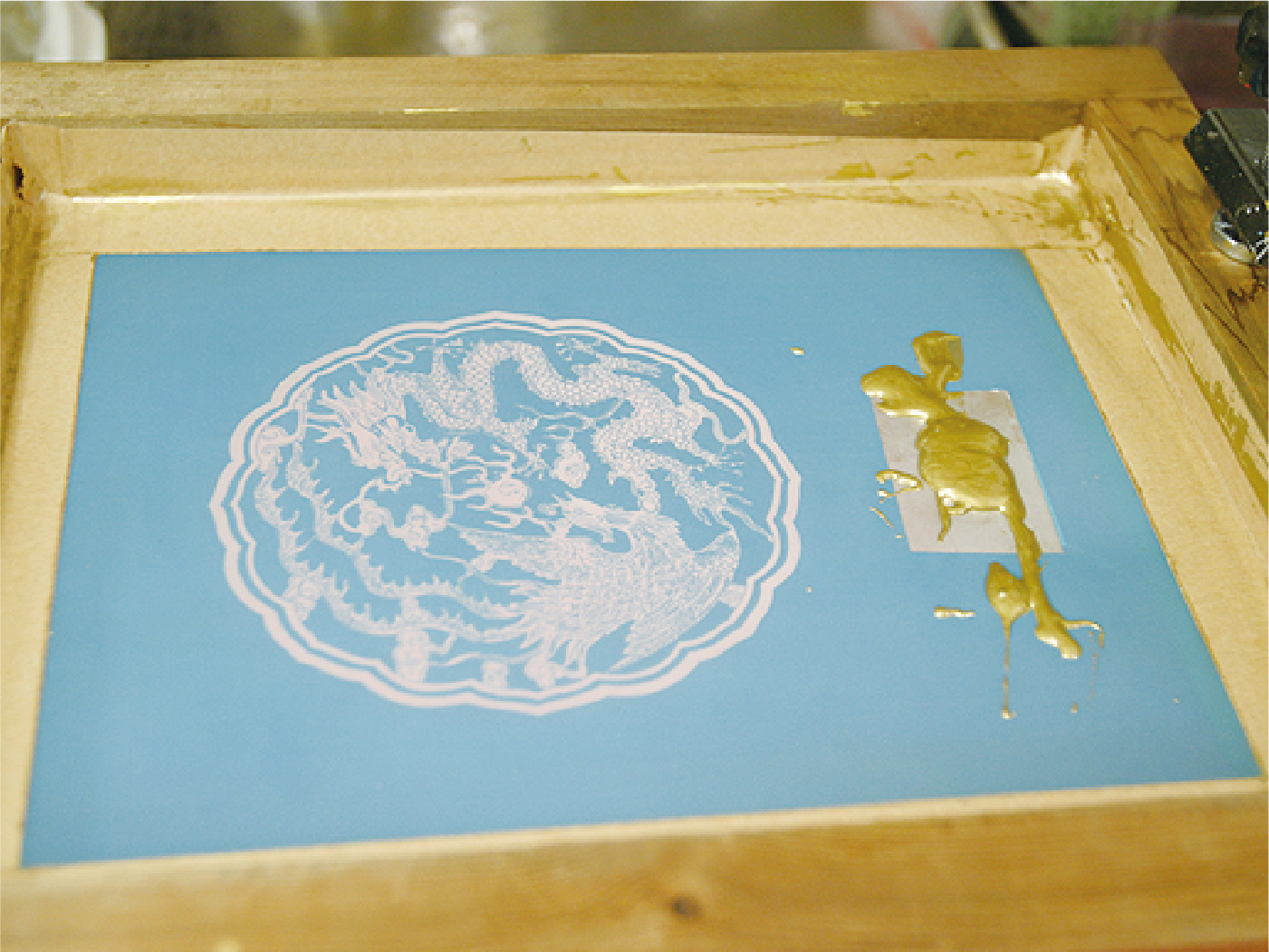

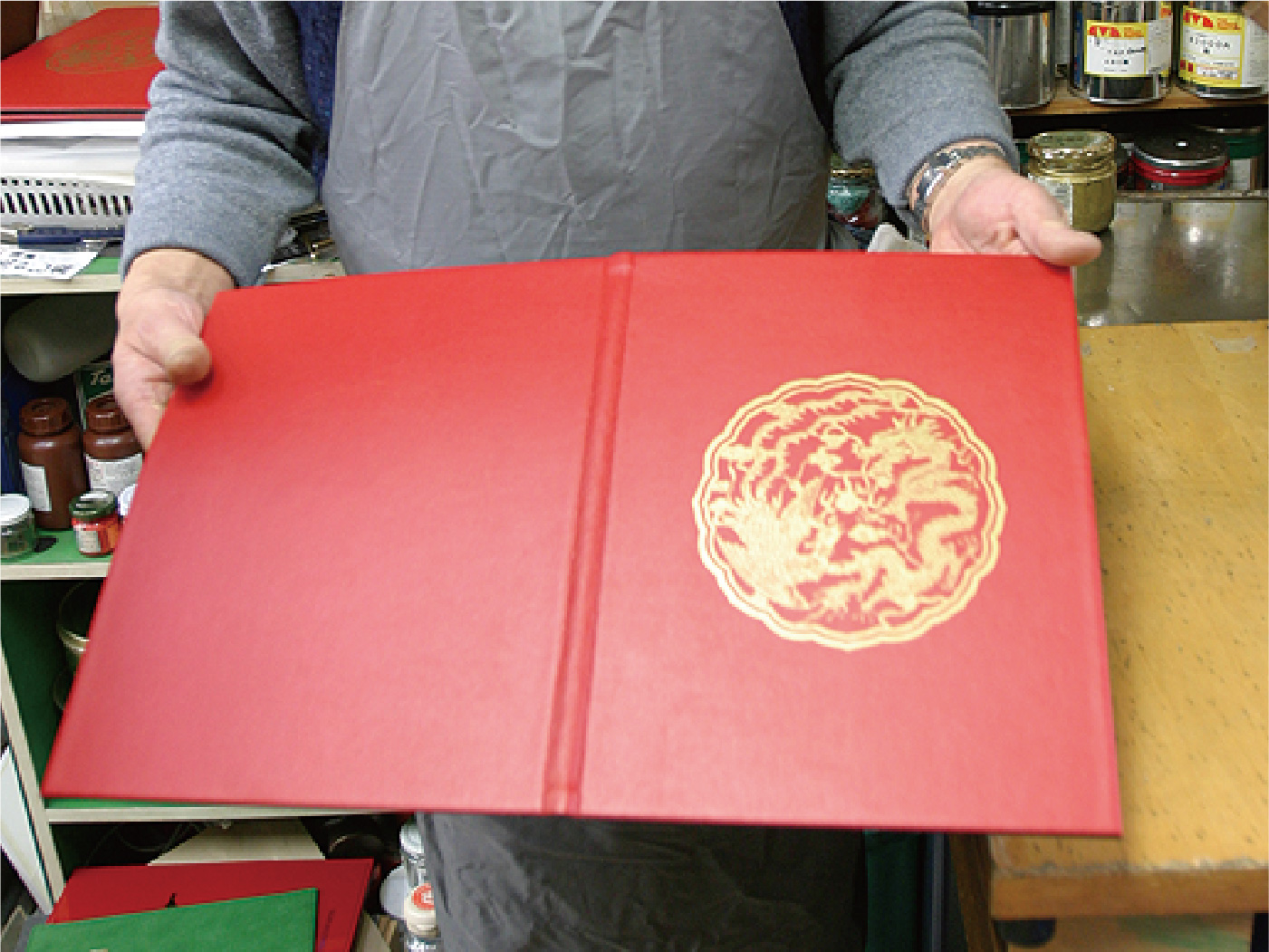

Screen printing

Screen printing refers to an ink transferring process passes through a screen, usually a net of mesh (net), such as nylon or tetrone, except in areas made impermeable to the ink.

[Features]

It’s good for various materials and shapes. In addition, ink colors can be adjusted to match with your special, ideal image. When your best color cannot be prepared, we are glad to suggest alternatives for you.

> Operation process

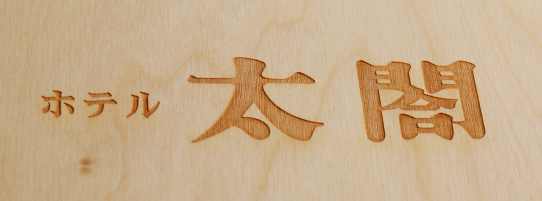

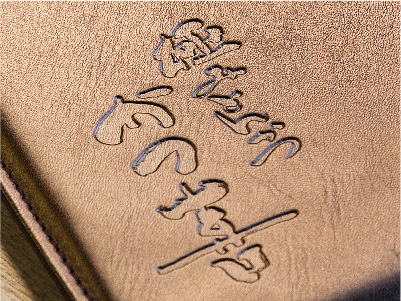

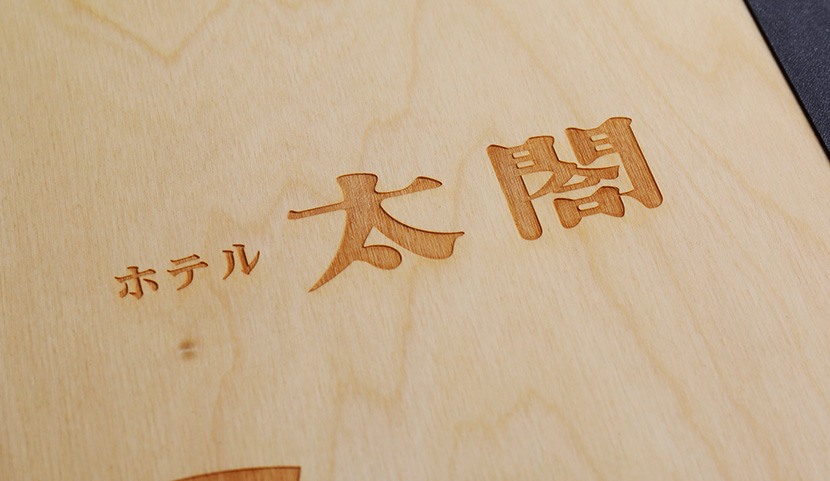

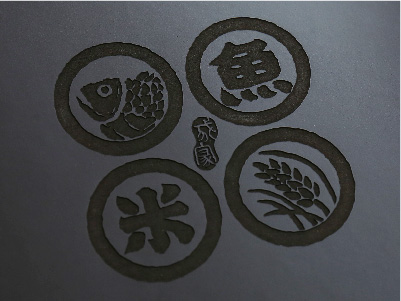

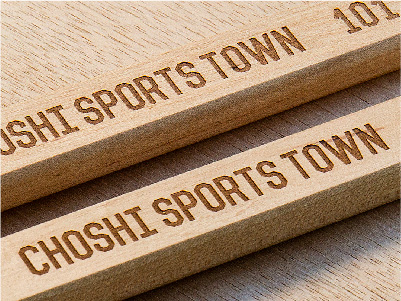

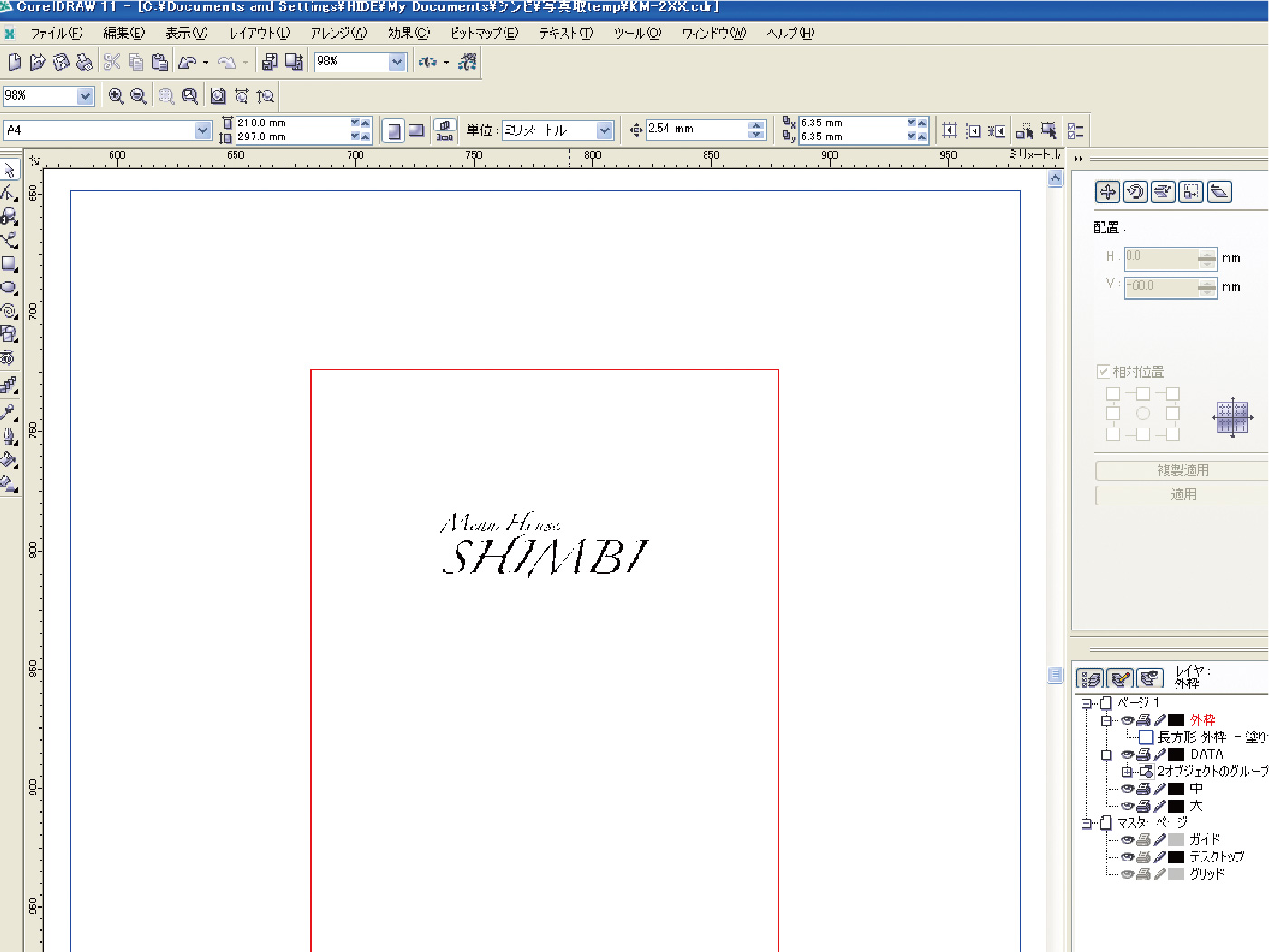

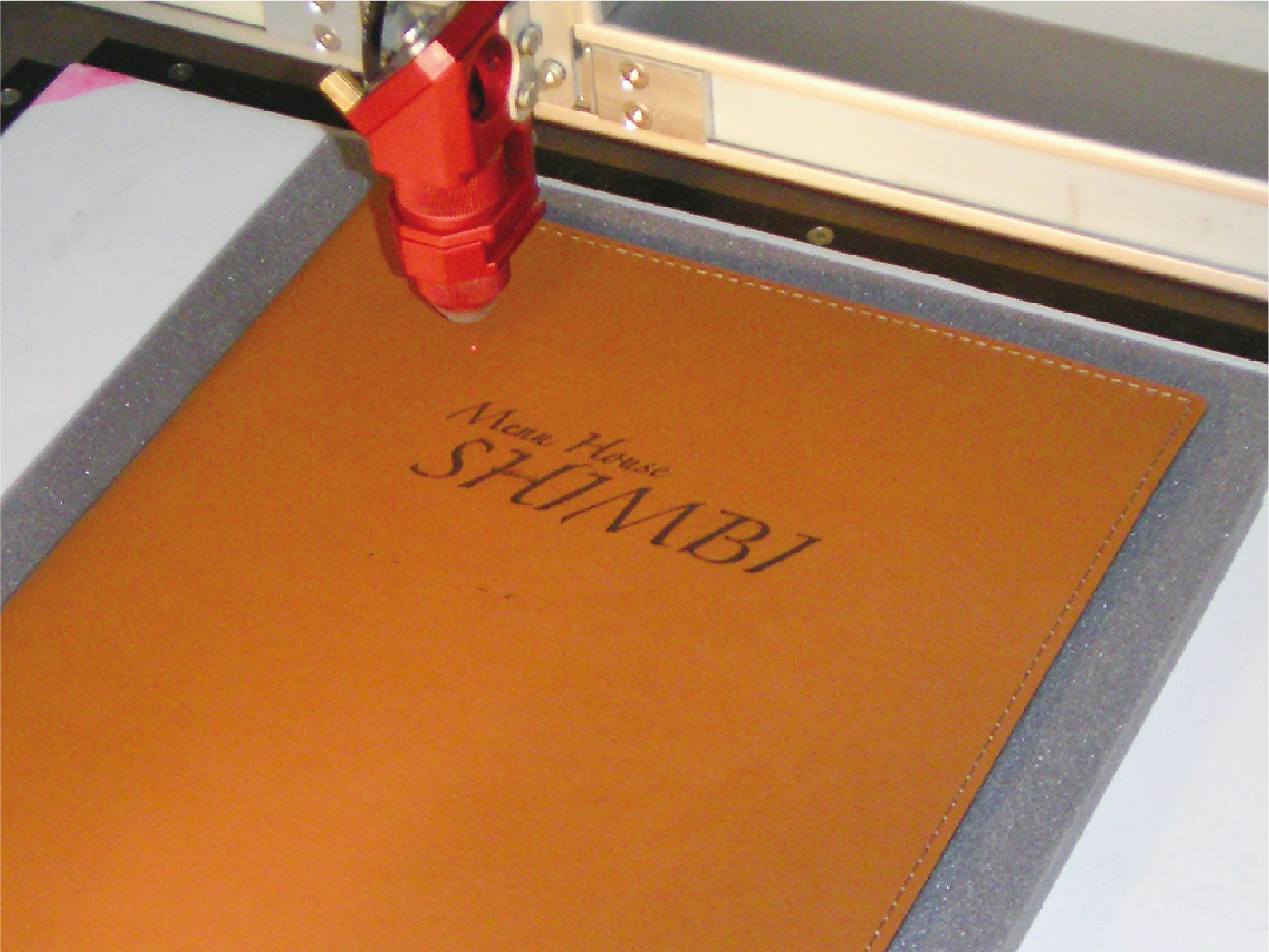

Laser Engraving

Laser engraving refers to “burning” the sculpting part by importing original script data into the printing device. It’s mainly used for the processing of wooden and acrylic products. The target area is like burned while the pattern is made into the material.

[Features]

Small-scale production is feasible as no printing plate is needed. It is relatively flexible in case of any changes in script data.

> Operation process

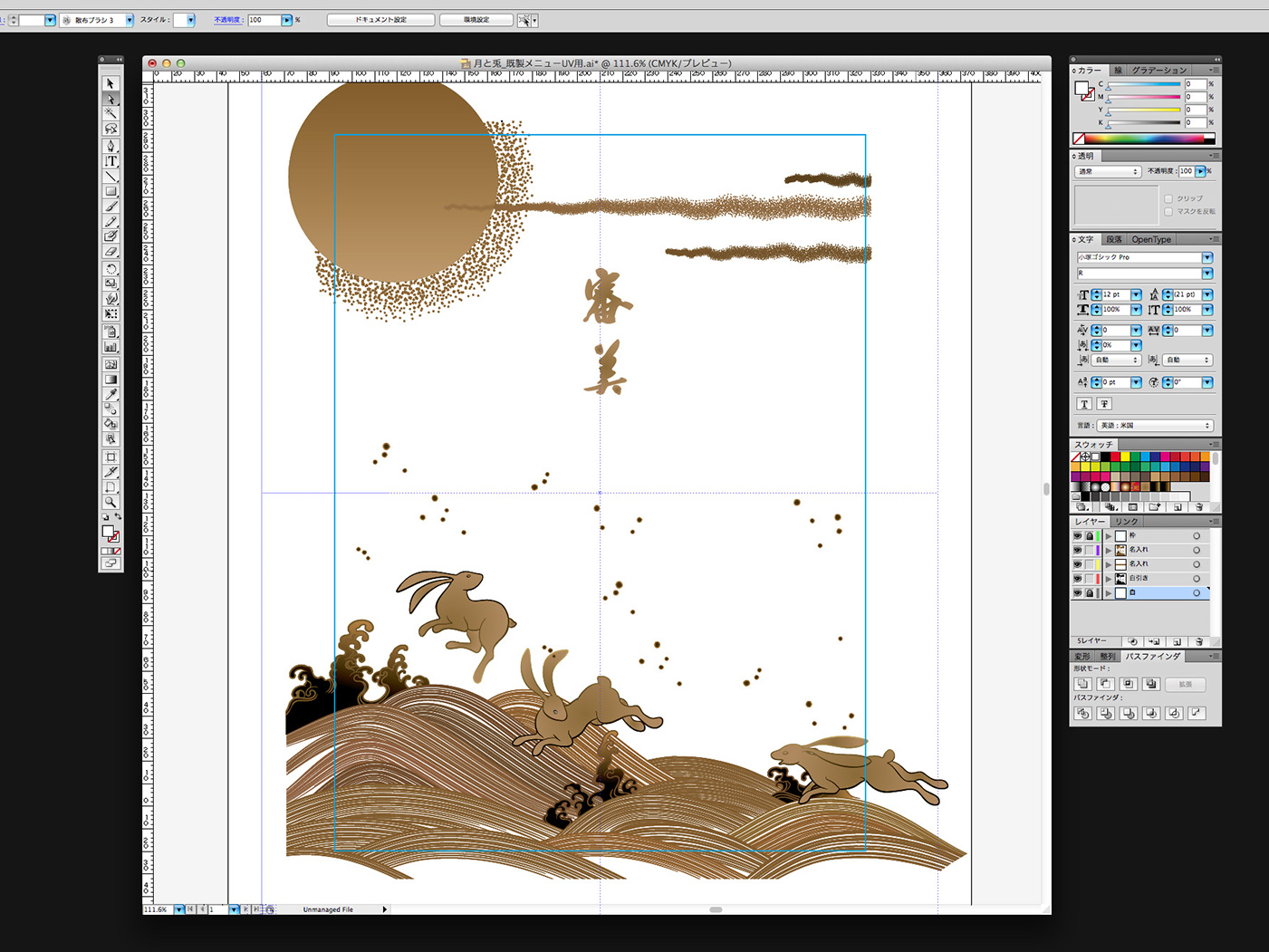

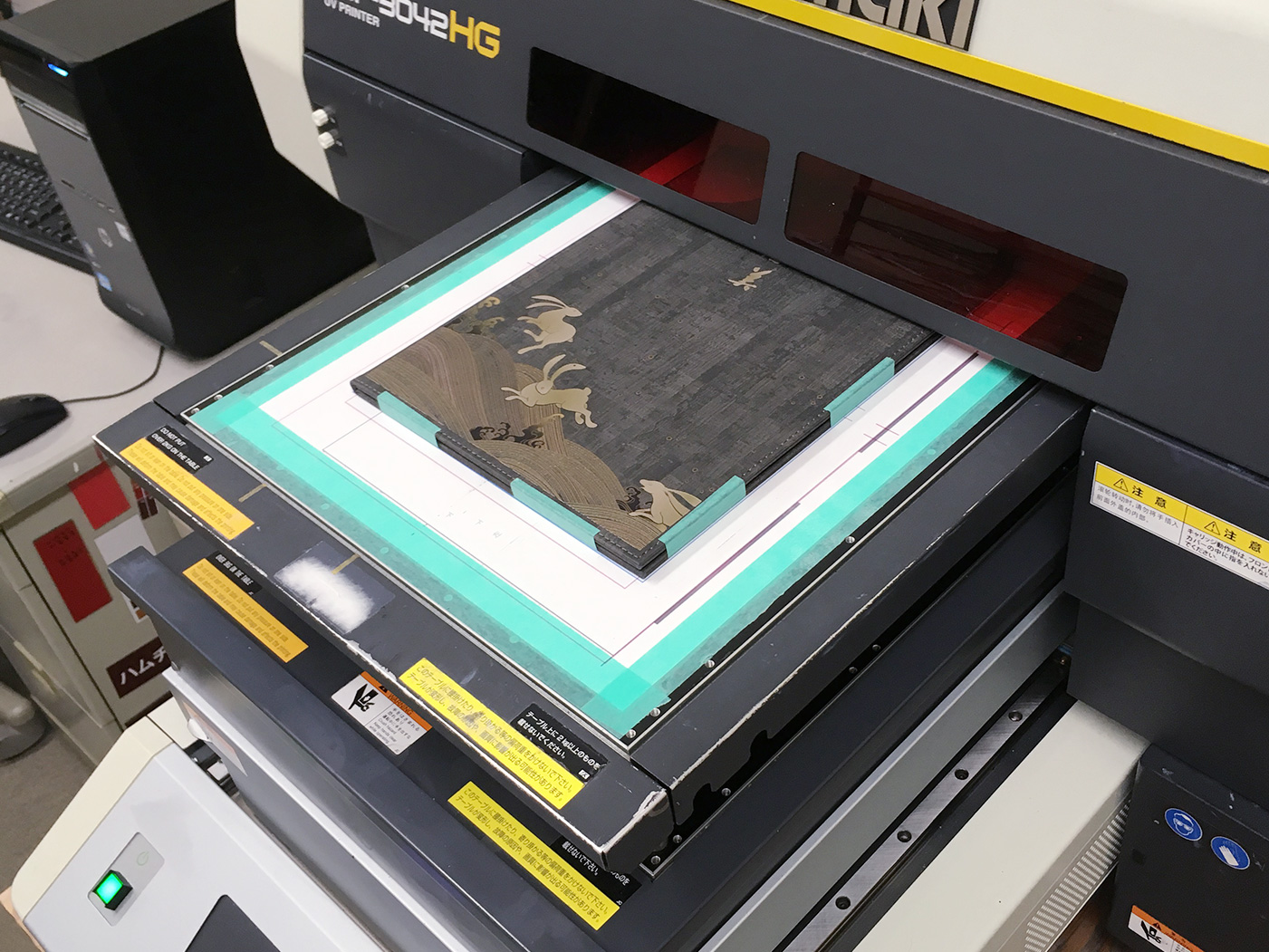

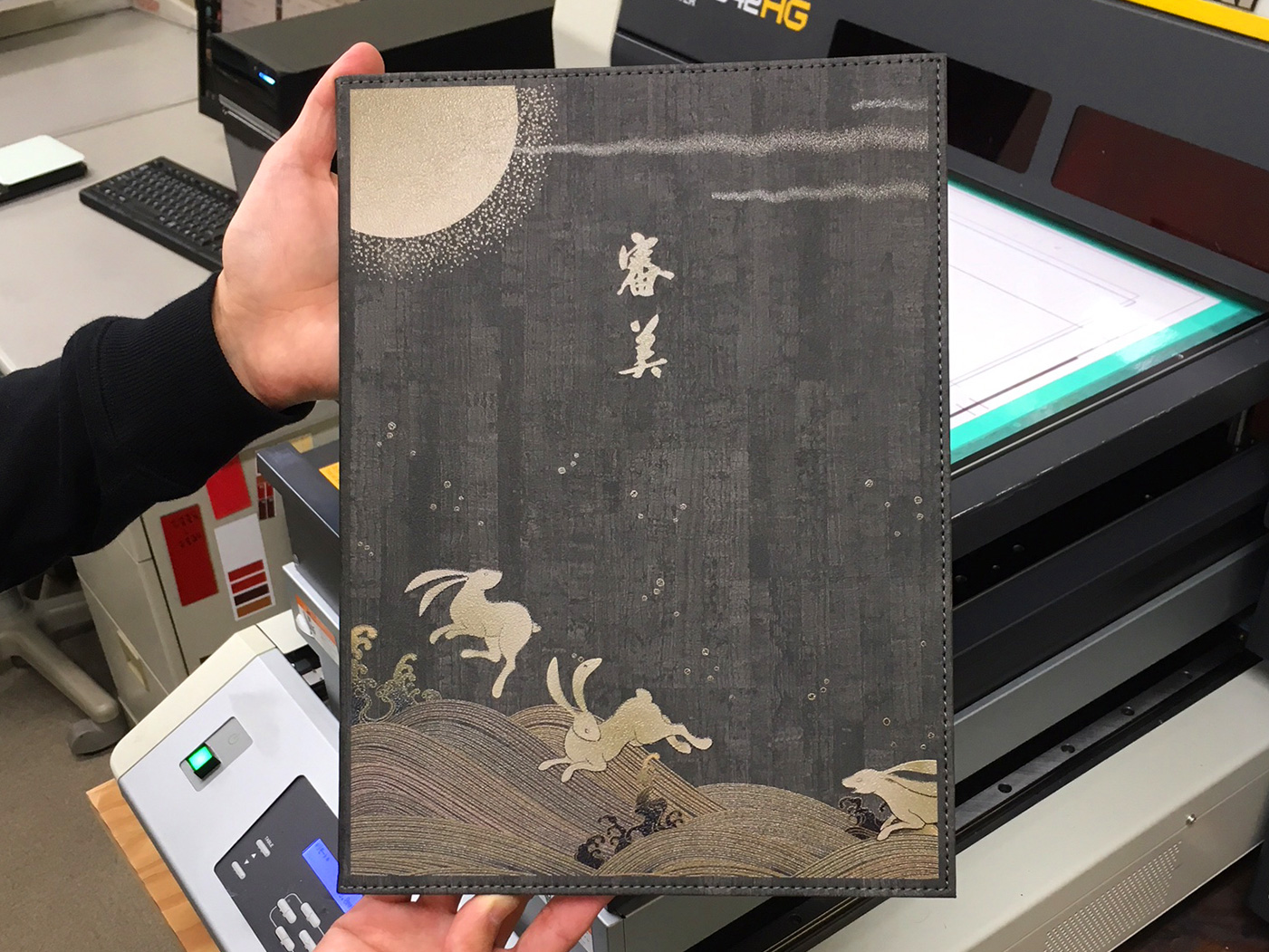

UV inkjet printing

The printing is done through digital data and without printing-plate so full-color and multiple colors printings are possible also for small lots.

[Features]

It is a detailed, fine printing good for materials with a rough surface and wooden surface with exhaustive gaps, and thus refined lines and extremely small words can be made. When compared with oily ink for screen printing, UV ink is harder, more friction and chemical resistant. Besides, it is environmental friendly as it is VOC (Volatile organic compounds)-free thus it is perfect for clients in the catering industry.

> Operation process